Over 30 Years of Experience in Woven Fabric Manufacturing

Welcome to the heart of HonryFabric, where each fabric begins its journey with a story of craftsmanship and innovation. Our Factory Show is a testament to our dedication to producing premium quality fabrics, from raw materials to finished products. Our modern facility is equipped with more than 130 advanced air-jet looms from industry leaders such as Murata, Toyota, and Tsudakoma, enabling a daily output of 250,000 meters. We deliver consistently high-quality woven fabrics tailored for garment applications, from everyday wear to functional apparel.

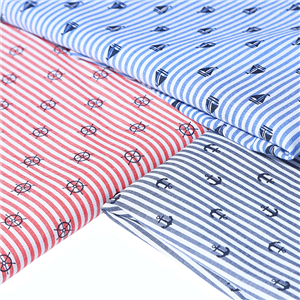

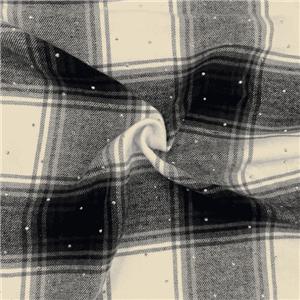

We specialize in a wide range of woven fabric types for clothing, including:

● Flannel, Poplin, and Seersucker

● Check and Stripe pattern fabrics

● Jacquard, Dobby, and Linen-style fabrics

● Denim Fabric for casual and workwear applications

● Functional Fabrics with moisture-wicking, UV-blocking, and anti-bacterial performance

Whether you're sourcing fabrics for mass production or looking to develop custom garment textiles, HonryFabric is your trusted manufacturing partner.

Our Full-Process Woven Fabric Manufacturing

Our vertically integrated process ensures quality at every stage: from raw material sourcing → spinning → dyeing → weaving → finishing → final inspection & packaging. This end-to-end control guarantees traceability, consistency, and efficiency.

Yarn Dyeing Process

——

At HonryFabric, the yarn dyeing stage marks the critical beginning of our production process. Using high-quality raw materials and advanced dyeing techniques, we ensure our yarns are uniformly colored and exhibit superior colorfastness. This step demonstrates our commitment to detail and our dedication to ensuring the enduring stability of our fabrics' colors.

Weaving Process

——

During the weaving phase, HonryFabric employs state-of-the-art loom technology, including renowned brands such as TOYOTA and TSUDAKOMA air-jet looms, to intricately weave our dyed yarns into fabric. Ourweaving technique not only ensures the aesthetic appeal and variety of our fabrics but also guarantees their structural strength and durability, meeting the diverse needs of our customers.

Finishing Process

——

The finishing process at HonryFabric is a crucial step in enhancing fabric quality. Here, we utilize world-class finishing equipment like MONFORTS to provide various treatments, such as softening, silk finishing, and wrinkle resistance, optimizing the feel and functionality of our fabrics. Additionally, we offer special functional treatments like waterproofing and quick-drying as per client requirements, showcasing our multifaceted production capabilities and commitment to innovation.

Quality Inspection Process

——

Quality inspection at HonryFabric is paramount. Our professional team conducts comprehensive checks on color, size, strength, and flaws to ensure that each batch of fabric meets our high standards. This rigorous inspection process reaffirms our promise of exceptional quality to our global clients and partners.

Certifications & Quality Assurance

Our operations are certified by OEKO-TEX Standard 100, GRS, OCS, and ISO9001. We conduct strict in-house inspections for colorfastness, shrinkage, and physical performance. Every batch is traceable and lab-tested. → View All Certificates

Looking for a reliable woven fabric supplier for your next apparel collection? Contact us today to discuss custom development, bulk orders, and production timelines.