What is Jacquard fabric made of

Introduction

If you work with fashion, home textiles or interior decoration, you have almost certainly touched jacquard fabric. From ornate upholstery to elegant dress fabrics, jacquard textiles stand out because their patterns are woven directly into the structure instead of being printed on the surface. For buyers and designers, a common question is: what is jacquard fabric actually made of, and how do its materials affect performance, hand-feel and cost?

In this article, we will explain the concept of jacquard fabric, how a jacquard loom controls each warp yarn, and what kinds of fibers and constructions are commonly used in woven jacquard and related jacquard textile products. This will help you choose the right quality for your product line.

What Is Jacquard Fabric?

Jacquard fabric is a woven textile in which complex patterns are created by varying the interlacing of warp and weft yarns, rather than by surface printing. The pattern can be geometric, floral, abstract or logo-based, and is integrated into the fabric itself.

The term “jacquard” comes from the Jacquard loom, invented in the early 19th century. On a traditional loom, groups of warp yarns move together, which limits pattern complexity. On a jacquard loom, each warp yarn can be raised or lowered independently thanks to a system of punched cards in the past, and now electronic controls. This allows extremely detailed, large-scale or multi-color patterns.

Key technical points:

The jacquard mechanism gives individual control of warp yarns.

Patterns are created by the weave structure, not by printing.

Color effects come from different yarn colors in warp and weft.

Print vs. Jacquard

It is important to distinguish between a printed fabric and jacquard fabric:

Printed fabric:

Base cloth is usually a simple weave (plain, twill, satin).

Design is applied on top using pigments or dyes.

Pattern can fade or crack with heavy use if not properly processed.

Jacquard fabric:

Pattern is formed directly in the weave.

Motifs can be seen on both face and back (sometimes as inverse colors).

Better resistance to abrasion and long-term use because the design is structural.

For buyers choosing fabric for high-wear applications—such as hotel upholstery or jacquard fabric for dresses in premium collections—this structural difference is a key factor.

What Is Jacquard Fabric Made Of?

When we ask “what is jacquard fabric made of?”, we are really talking about two dimensions:

Fiber composition – what raw materials are used in the yarns.

Construction – how these yarns are organized and interlaced.

Both aspects determine the final performance, drape, cost and market positioning of the fabric.

Common Fiber Compositions

Below are the most common compositions found in jacquard fabric for apparel and home textiles.

100% Cotton Jacquard

A classic option for shirts, dresses, table linens and bedding.Comfortable and breathable.

Natural look and soft hand-feel.

Good dye uptake with rich colors.

Suitable for cotton jacquard fabric in mid-weight or lightweight constructions.

Cotton/Polyester Blend Jacquard

Often used in casual wear, uniforms, and home textiles.Combines cotton comfort with polyester durability.

Improved wrinkle resistance.

More stable shrinkage and better dimensional stability.

Popular for cost-effective jacquard fabric for dresses and decor projects.

100% Polyester Jacquard

Widely used in curtains, hotel upholstery and contract textiles.High strength and abrasion resistance.

Excellent color fastness and light fastness.

Easy-care and quick-dry properties.

Can create lustrous, satin-like effects at a competitive price.

Viscose/Polyester Jacquard

Used where a more luxurious, fluid drape is required.Viscose provides silk-like sheen and softness.

Polyester contributes strength and crease resistance.

Suitable for fashion garments and drapery with flowing silhouettes.

Jacquard with Spandex

A small percentage of elastane/spandex (e.g., 2–5%) is used in some jacquard fabric for dresses, pants or fitted jackets.Provides stretch and recovery.

Improves comfort and mobility.

Enhances body-fitting shape without sacrificing pattern clarity.

Silk and Silk-Blend Jacquard

Silk jacquard fabric is typically used in high-end fashion, luxury scarves and occasion wear.Natural sheen and elegant drape.

Excellent handle with a premium look.

Can be blended with viscose or polyester to balance cost and performance.

Special Functional Blends

Some mills offer jacquard qualities with special fibers such as recycled polyester, linen, or even functional yarns (for example, moisture management or thermal regulation). These materials support sustainability goals and performance-driven products.

To summarize, jacquard fabric is not defined by one specific fiber. Instead, it is defined by how the pattern is woven. The same jacquard design can be produced in multiple fiber options to match different target markets and price levels.

Construction & Weave Structure

Beyond fiber composition, the construction of jacquard fabric plays a crucial role in its appearance and performance.

Dobby vs. Jacquard

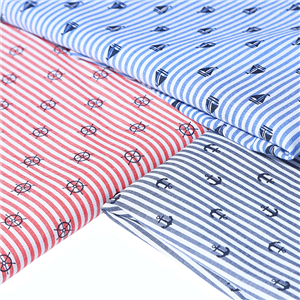

Dobby weave:

Controls small groups of warp yarns.

Suitable for simpler geometric patterns (stripes, small checks, basic repeats).

More limited in pattern scale and complexity.

Jacquard weave:

Controls each warp yarn individually.

Suitable for large-scale florals, pictorial designs, intricate logos and detailed motifs.

Enables complex repeat sizes and multiple weave structures within one design.

A buyer looking for floral jacquard fabric with detailed petals and shading will typically choose a full jacquard construction instead of a dobby weave.

Yarn Count and Density

Yarn count (fineness) and density (ends and picks per inch/cm) directly influence:

Fabric weight and coverage.

Hand-feel (crisp vs. soft).

Pattern clarity (sharp vs. fuzzy edges).

Durability and abrasion resistance.

High-density jacquard fabric with fine yarns can deliver extremely sharp patterns and luxurious handle, making it suitable for high-end garments and decorative fabrics.

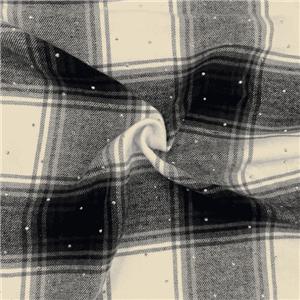

Warp and Weft Selection

In jacquard weaving, the mill can combine different yarns between warp and weft:

Filament yarns in warp and spun yarns in weft for subtle surface texture.

Different colors in warp and weft to achieve reversible or two-tone effects.

Core-spun yarns or slub yarns to add additional visual interest.

All these choices are part of what jacquard fabric is “made of” in the structural sense.

Types of Jacquard Fabric

Several classic categories of jacquard fabric are commonly recognized in the market.

Brocade

Brocade is a rich, often heavy jacquard with raised patterns that look almost embroidered. It is widely used in ceremonial garments, traditional wear, and decorative upholstery.

Damask

Damask is a reversible jacquard, typically created with a combination of satin and sateen weaves. It is frequently found in table linens, bedding and classic interior textiles.

Matelassé

Matelassé is a quilted-look jacquard fabric that appears padded or embossed, although it may not contain actual padding. It is commonly used in coverlets, bedspreads and some outerwear.

Jacquard Knit

While this article focuses mainly on wovens, jacquard principles also apply to knitted fabrics. Jacquard knits use different colored yarns and stitch structures to create patterns within the knit. They are often used in sweaters, sportswear and casual jacquard fabric for dresses.

Embossed Jacquard

In embossed jacquard, the woven pattern can be combined with mechanical or chemical embossing to enhance the three-dimensional effect. This is popular in modern home textiles and fashion accessories.

Among these, floral jacquard fabric can appear in brocade, damask or knit categories, depending on the design and end use.

Key Characteristics of Jacquard Fabric

Because of its structure and design flexibility, jacquard fabric has several notable characteristics.

Three-dimensional pattern effect

Patterns can appear raised or recessed, providing depth and a premium look.Durable design

Since the motif is woven into the fabric, it resists fading and surface damage better than many printed designs.Color versatility

Multiple colored yarns can be used in warp and weft to create intricate color combinations.High-end appearance

The structural patterns give jacquard fabric a more sophisticated and premium look, suitable for mid- to high-end markets.Wide weight range

From lightweight silk jacquard fabric for dresses to heavy upholstery qualities, the same technology can cover many market segments.

How Jacquard Fabric Is Produced

Modern jacquard production combines traditional weaving know-how with advanced digital technology. A typical process in a professional woven mill like honryfabric includes:

Yarn and Warp Preparation

Selection of fiber composition, yarn count and twist.

Warping: arranging warp yarns in the correct order and tension.

Sizing: applying protective size to improve weaving efficiency and reduce breakage.

Jacquard Design and Programming

Designers create pattern artwork and translate it into weave structures.

Digital jacquard systems control each warp yarn based on the design file.

This enables quick modification and sampling for different customers.

Weaving on Electronic Jacquard Looms

Electronic jacquard heads control thousands of hooks.

High-speed looms deliver stable, consistent jacquard fabric production.

Mills can quickly switch between different designs on the same machine platform.

Dyeing and Finishing

Depending on whether the fabric is yarn-dyed or piece-dyed, mills perform:Dyeing for color development.

Heat-setting and dimensional stabilization.

Softening, brushing, calendaring, coating or other functional finishes.

Inspection and Quality Control

Visual check of pattern accuracy and color consistency.

Testing for strength, shrinkage, color fastness and other requested parameters.

For buyers who want to understand mill capacity and technical capabilities, it is helpful to explore a factory’s background. You can see an example of a woven fabric manufacturing setup with over 30 years of experience here:

https://www.honryfabric.com/factory/over-30-years-of-experience-in-woven-fabric-manufacturing

Applications of Jacquard Fabric

Because of its structural patterning and broad range of compositions, jacquard fabric is used in many sectors:

Decorative fabrics

Curtains, drapery, upholstery, cushions.

Hotel and contract interiors where design and durability are both important.

High-end apparel

Evening wear, structured jackets, skirts and jacquard fabric for dresses.

Statement pieces with rich patterns, including floral jacquard fabric.

Bedding and home textiles

Duvet covers, bedspreads, pillow shams, matelassé coverlets.

Damask constructions are especially common in this category.

Workwear and uniforms

Where a subtle pattern is needed for branding or differentiation.

Blended cotton jacquard fabric and polyester jacquard are often chosen.

Bags and accessories

Fashion bags, straps, belts, and decorative trims.

Logo jacquard textiles that support brand identity.

Many brands combine jacquard with other structured weaves such as seersucker to build a complete product line. For comparison, you can see a range of seersucker products here:

https://www.honryfabric.com/product-list/seersucker-fabric

Advantages of Jacquard Fabrics from Our Factory

When sourcing jacquard fabric, the manufacturing partner’s capability is as important as the fabric itself. A factory like honryfabric offers several advantages:

Integrated weaving center

In-house warping, sizing and weaving for better quality control and lead time management.

Digital jacquard technology

Electronic jacquard looms that can handle complex and large-scale designs.

Ability to develop customized cotton jacquard fabric, silk jacquard fabric and blends.

Customizable compositions

Wide range of options: cotton, CVC, TC, polyester, viscose, and stretch blends.

Support for different weight ranges, from light jacquard fabric for dresses to heavy upholstery.

Certified production

Ability to produce according to standards such as Oeko-Tex and ISO, depending on customer requirements.

Experience with international brands

Long-term export experience serving global retailers and brands.

Stable quality and consistent bulk production.

Rich jacquard pattern library

Existing collections of geometric, stripe, and floral jacquard fabric designs.

Custom development service based on customers’ CAD, artwork or physical samples.

You can explore real application examples and customer projects in the case section:

https://www.honryfabric.com/case

For a more focused view of available jacquard styles, you can also visit the dedicated jacquard category:

https://www.honryfabric.com/product-list/jacquard-fabric

How to Choose the Right Jacquard Fabric

For sourcing teams, designers and buyers, selecting the right jacquard fabric involves balancing design, performance and budget. Below is a practical framework.

1. Match Composition to End Use

| End Use | Recommended Composition | Notes |

|---|---|---|

| Dresses & fashion apparel | cotton jacquard fabric, viscose/poly, silk jacquard fabric, stretch jacquard | Focus on drape, comfort and visual impact |

| Formalwear & occasion wear | silk jacquard fabric, viscose blends | High sheen and fine pattern resolution |

| Upholstery & contract use | Polyester or poly-rich blends | High abrasion resistance and color fastness |

| Bedding & home textiles | Cotton, CVC, cotton/poly blends | Comfort and breathability with sufficient strength |

2. Choose Weight and Density

Lightweight (80–150 g/m²): suitable for blouses, linings, summer jacquard fabric for dresses.

Medium weight (150–260 g/m²): shirts, dresses, decorative cushions, light curtains.

Heavy weight (260 g/m² and above): upholstery, structured jackets, outerwear and bedspreads.

Higher density generally provides sharper patterns and better durability but may increase cost.

3. Evaluate Hand-Feel and Drape

Handle and drape are critical for apparel and curtain use:

For flowing floral jacquard fabric in dresses, look for viscose-rich or fine denier constructions.

For crisp, sculptural shapes (such as tailored jackets), firmer constructions or heavier blends are more suitable.

4. Consider Finishing Options

Finishing can dramatically change the character of jacquard fabric:

Softening: for a smoother, more pleasant touch.

Calendering or embossing: for extra sheen or surface effect.

Coating or back-finishing: for upholstery, blackout or functional applications.

Discuss finishing options with the mill to ensure performance matches your product requirements.

5. MOQ and Color Strategy

For B2B sourcing, MOQ is always a practical factor:

Yarn-dyed jacquards (especially multi-color effects) generally require higher MOQs and longer lead times.

Piece-dyed jacquards can sometimes offer more flexibility in color without changing the base weave.

Working with a mill that maintains greige jacquard fabric stock for standard constructions can help balance flexibility and cost.

FAQs

What is the main difference between jacquard fabric and ordinary woven fabric?

Ordinary woven fabrics usually use simple weaves such as plain, twill or satin with limited pattern capability. Jacquard fabric uses a jacquard mechanism to control individual warp yarns, enabling complex patterns that are integrated into the structure instead of being printed.

Can jacquard fabric be used for everyday dresses?

Yes. Many fashion brands use jacquard fabric for dresses in both casual and occasion wear. By choosing appropriate compositions—such as cotton jacquard fabric, viscose blends or lightweight silk jacquard fabric—you can achieve different levels of comfort, drape and price.

Is jacquard fabric always heavy and stiff?

Not necessarily. While some upholstery and brocade qualities are heavy, mills can produce light and soft jacquard fabric with fine yarns and suitable finishes. There are many options designed for blouses, shirts and lightweight dresses.

How does floral jacquard compare with printed floral fabric?

In floral jacquard fabric, the floral motif is formed by the weave structure, giving a more textured and durable pattern. Printed floral fabrics rely on surface prints, which may offer more photo-realistic details but are more dependent on printing technology and finishing quality.

Does jacquard fabric require special care?

Care instructions depend on composition. For example, polyester-based jacquard fabric is usually easy-care and machine washable, while silk jacquard fabric may require dry-cleaning. Always follow the recommended care label based on the specific fabric quality.

Conclusion

Understanding what jacquard fabric is made of means looking at both its fiber composition and its structural design. Jacquard technology allows mills to combine cotton, polyester, viscose, silk, spandex and other fibers into patterned woven textiles that serve apparel, home textiles and contract applications. Practical decisions—such as choosing cotton jacquard fabric for breathable comfort, silk jacquard fabric for luxury, or durable blends for upholstery—depend on your end use, target market and brand positioning. By working closely with a capable weaving factory, you can select or develop the exact jacquard fabric quality that matches your needs in terms of design, performance and cost.