What is Linen Fabric

The Origin and History of Linen

Linen fabric dates back more than 10,000 years, making it one of the earliest known textiles in human history. Ancient Egyptians cultivated flax and wove linen for clothing, burial garments, and temple textiles. The linen fabric texture symbolized purity and status, even used to wrap royal mummies.

In medieval Europe, linen became a household essential for bed sheets, undergarments, and tablecloths — giving rise to the term table linen fabric still used today.

By the 19th century, industrial spinning and weaving transformed linen into a globally traded commodity, with production centers in Ireland, Belgium, and France.

Today, China has become the largest producer and exporter of linen, combining traditional craftsmanship with modern weaving technology to deliver consistent quality at competitive prices.

How Is Linen Fabric Made

The manufacturing process of linen fabric requires time, patience, and precision. Unlike synthetic fibers, linen is made entirely from the flax plant, and every step influences the final fabric’s texture, appearance, and durability.

1. Flax Cultivation

Flax grows best in cool, moist climates such as Northern Europe and Northern China. The plant matures in 100 days and requires minimal pesticides or fertilizers, making it an eco-friendly crop. Farmers harvest the entire plant, not just the seed, to preserve the longest fibers possible.

2. Retting and Scutching

After harvesting, flax stalks are soaked in water (retting) to loosen the fibers from the woody stem. Then scutching removes the woody parts, leaving long, soft fibers ready for spinning. This stage determines much of the linen fabric texture and softness.

3. Spinning

The fibers are spun into yarns using either wet or dry spinning techniques. Wet spinning creates smoother and finer yarns suitable for apparel, while dry spinning produces coarser yarns ideal for upholstery or table linen fabric.

4. Weaving

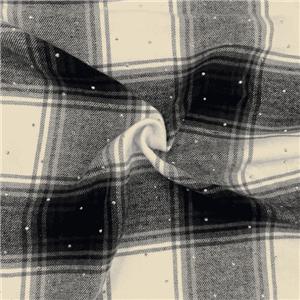

The yarns are woven into various structures—plain, twill, or damask—depending on the desired types of linen fabric.

For example:

| Weave Type | Description | Typical Use |

|---|---|---|

| Plain Weave | Simple, tight, durable | Clothing, shirts |

| Twill Weave | Diagonal texture | Pants, upholstery |

| Damask | Patterned with jacquard | Tablecloths, luxury linens |

5. Finishing

Finishing includes washing, bleaching, dyeing, or enzyme softening. Modern manufacturers often use enzyme washing and low-impact dyes to enhance softness and reduce environmental impact. A well-finished linen fabric cotton blend feels smoother and resists wrinkling better than untreated versions.

Characteristics and Benefits of Linen Fabric

Linen fabric is favored across industries for its distinctive performance and natural aesthetics. Key advantages include:

Breathable and moisture-wicking: Linen absorbs up to 20% of its weight in moisture before feeling damp, making it ideal for warm climates.

Naturally hypoallergenic: Suitable for sensitive skin, unlike many synthetic fibers.

High durability and strength: 30% stronger than cotton; retains shape after repeated washes.

Sustainable and biodegradable: Derived from renewable flax, decomposes naturally.

Elegant texture and drape: The unique linen fabric texture delivers a crisp, natural appearance appreciated in high-end fashion and interior design.

Temperature regulation: Keeps you cool in summer and warm in cooler weather due to its natural fiber structure.

Static and lint resistant: A professional benefit for upholstery and linen fabric clothing manufacturing.

Types of Linen Fabric

Linen fabric comes in various compositions and constructions depending on its intended use. Below are the most common types of linen fabric:

| Type | Composition | Applications | Key Features |

|---|---|---|---|

| Pure Linen | 100% flax fiber | Premium shirts, dresses | Crisp texture, breathable |

| Cotton and Linen Fabric | 50–70% linen + cotton | Casual wear, bedding | Soft, wrinkle-resistant |

| Blended Linen | Linen + viscose/polyester | Affordable clothing | Smooth and easy-care |

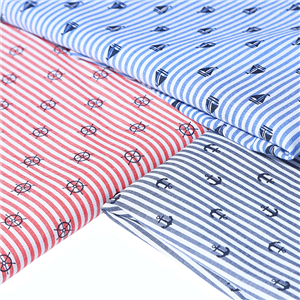

| Yarn-Dyed Linen | Pre-dyed yarns woven | Shirts, tablecloths | Colorfast, vibrant |

| Printed Linen | Surface printed | Home décor, fashion | Diverse patterns |

| Heavy Linen | Thick yarns | Upholstery, curtains | Durable and structured |

| Lightweight Linen | Fine yarns | Summer clothing | Airy and flexible |

Blends such as cotton and linen fabric or linen fabric cotton offer both the comfort of cotton and the elegance of linen, reducing cost while maintaining a natural feel.

Common Applications of Linen Fabric

Linen fabric is versatile and serves both fashion and industrial markets.

1. Apparel and Fashion

Linen fabric clothing includes shirts, trousers, skirts, and summer dresses. Designers favor it for its breathable nature and sophisticated texture. Premium brands often use yarn-dyed linen for depth and color stability.

2. Home Textiles

Table linen fabric, curtains, napkins, and bedding sets are classic home applications. Linen’s absorbency and durability make it ideal for restaurants, hotels, and luxury households.

3. Industrial and Decorative Use

In the B2B sector, linen appears in wall coverings, upholstery, and even in high-strength industrial textiles. Some automotive interiors also use linen fabric cotton blends to achieve a natural, tactile finish.

Main Production Regions and Global Market

Linen fabric production is concentrated in specific regions with optimal flax-growing conditions.

| Country/Region | Key Features | Market Share (Approx.) |

|---|---|---|

| China | Advanced spinning, competitive pricing, large export volume | 55% |

| Belgium | European Flax® certified, high-quality yarns | 15% |

| France | Fine long-staple flax, sustainable practices | 10% |

| Italy | Luxury linen finishing, fashion-grade products | 8% |

| Others | Lithuania, India, Turkey | 12% |

China leads in both raw flax cultivation and finished fabric export, offering the widest selection of types of linen fabric at varying price points. With global demand for sustainable materials rising 12% annually, linen’s market share continues to expand, particularly in eco-conscious apparel and home décor industries.

Linen Fabric Price Factors

The cost of linen fabric varies depending on several B2B factors:

| Factor | Description | Impact on Price |

|---|---|---|

| Yarn Quality | Long-staple flax yields smoother fabric | +15–25% |

| Weaving Density | Higher thread count enhances durability | +10–20% |

| Finishing | Enzyme wash, bleaching, or printing | +5–15% |

| Order Quantity | Bulk orders reduce cost per meter | –10–30% |

Typical wholesale prices range between USD 3–10 per meter, depending on quality and finish.

Blends like cotton and linen fabric are often priced 20–30% lower than 100% pure linen, offering an affordable alternative for mid-market buyers.

Environmental Impact and Sustainability of Linen

One of the biggest advantages of linen fabric is its eco-friendliness. Flax requires 60% less water than cotton and can grow without irrigation in most climates. Additionally, almost every part of the flax plant is usable—seeds for oil, fibers for fabric, and shives for paper—creating a zero-waste production chain.

Compared to synthetic fibers like polyester, linen generates 35–50% less carbon emissions during its lifecycle. Even cotton and linen fabric blends significantly reduce microplastic pollution.

Modern mills increasingly adopt water recycling, natural dyeing, and bio-based finishing technologies to further improve sustainability performance.

Certifications and Standards

Reliable linen fabric suppliers adhere to global certifications that ensure environmental responsibility and product safety. Major standards include:

OEKO-TEX Standard 100 – Confirms no harmful substances in textiles.

GOTS (Global Organic Textile Standard) – Certifies organic linen production.

European Flax® – Guarantees traceability and European-origin flax.

ISO9001 – Ensures consistent quality management and manufacturing control.

For international buyers, choosing certified suppliers reduces sourcing risks and aligns with sustainability targets set by global retailers.

FAQ about Linen Fabric

Q1: Is linen better than cotton?

Yes. Linen fabric is stronger, more breathable, and more sustainable than cotton. However, cotton and linen fabric blends combine the softness of cotton with linen’s strength, offering a balanced option.

Q2: Does linen shrink?

Pure linen may shrink slightly (2–5%) on first wash, so pre-washed or enzyme-treated fabrics are recommended for production.

Q3: How to care for linen fabric?

Wash gently in cool water, avoid bleach, and iron while slightly damp. Proper care preserves the elegant linen fabric texture.

Q4: Is linen eco-friendly?

Absolutely. Linen is made from renewable flax, requires minimal pesticides, and is fully biodegradable.

Q5: What are the best uses for table linen fabric?

Table linen fabric is perfect for restaurants, hotels, and event suppliers due to its absorbency and upscale appearance.

Q6: What are the main types of linen fabric available for clothing?

Lightweight and linen fabric cotton blends are most suitable for apparel, offering softness and comfort with durability.

Explore Premium Linen Fabrics at Honry Fabric

At Honry Fabric, we combine decades of weaving expertise with sustainable production practices to deliver premium linen fabric and cotton and linen fabric solutions for global buyers. Our collections include yarn-dyed, jacquard, and printed linens, as well as custom blends tailored to fashion, home, and industrial use.

With OEKO-TEX and ISO9001 certifications, we ensure quality consistency from raw flax to finished rolls. Discover our full product range and request a bulk quotation through our official website:

👉 https://www.honryfabric.com/