What is the difference between knit and woven fabric?

When sourcing fabrics for apparel, home textiles, or industrial applications, one of the most common — and most important — questions buyers ask is: what is the difference between knit and woven fabric?

This question is at the core of fabric selection because the structure of a fabric directly affects its performance, cost, durability, comfort, and suitability for end use.

For global buyers, garment manufacturers, brand owners, and sourcing managers, understanding woven fabric versus knit fabric is not just a technical issue — it is a commercial decision that impacts product positioning, supply chain efficiency, and customer satisfaction.

In this in-depth guide, we will explore knit vs woven fabric from every angle: construction methods, physical properties, applications, cost structure, sustainability trends, and sourcing considerations. You will also find data comparisons, tables, and practical insights to help you choose the right textile woven fabric or knit fabric for your next project.

Understanding Fabric Construction: The Foundation of Knit vs Woven Fabric

Before comparing performance and applications, it is essential to understand how fabrics are constructed.

What Is Woven Fabric?

Woven fabric is made by interlacing two sets of yarns at right angles:

Warp yarns (vertical)

Weft yarns (horizontal)

These yarns cross each other on a loom, creating a stable, structured fabric.

Common examples include:

Plain weave

Twill weave

Satin weave

Because of this interlaced structure, textile woven fabric is known for its dimensional stability, strength, and clean appearance.

What Is Knit Fabric?

Knit fabric is created by interlooping yarns rather than interlacing them. This looping structure allows the fabric to stretch naturally.

There are two main types:

Weft knitting (e.g., jersey, rib)

Warp knitting (e.g., tricot, interlock)

Knit fabrics are widely used where flexibility and comfort are required.

Knit vs Woven Fabric: Structural Differences Explained

The fundamental difference between knit and woven fabric lies in yarn interaction.

| Aspect | Woven Fabric | Knit Fabric |

|---|---|---|

| Construction | Interlaced yarns | Interlooped yarns |

| Stability | High | Medium to low |

| Stretch | Low (unless blended) | Naturally high |

| Shape retention | Excellent | Moderate |

| Edge fraying | Yes | No |

This structural difference is the reason woven fabric clothing is commonly used for tailored garments, while knit fabrics dominate casual and activewear.

Physical Properties Comparison: Knit vs Woven Fabric

Strength and Durability

Woven fabric is generally stronger than knit fabric due to its tight yarn interlacing. This makes it suitable for:

Uniforms

Workwear

Upholstery

Home textiles

Knit fabrics, while flexible, can be more prone to snagging and distortion under tension.

Stretch and Comfort

Knit fabrics offer natural elasticity without the need for elastane. This makes them ideal for:

T-shirts

Sportswear

Loungewear

In contrast, woven cotton fabric typically requires mechanical stretch or fiber blending to achieve flexibility.

Breathability and Airflow

Both fabric types can be breathable, depending on yarn type and fabric density.

Lightweight textile woven fabric such as poplin or voile provides excellent airflow.

Knits like jersey offer breathability with added comfort.

The choice depends on climate, garment purpose, and end-user expectations.

Applications: Where Knit and Woven Fabrics Are Used

Woven Fabric Applications

Woven fabric clothing dominates many professional and fashion categories:

Shirts and blouses

Trousers and chinos

Jackets and coats

Dresses and skirts

Bedding and curtains

Woven cotton fabric is especially popular due to its balance of comfort, durability, and breathability.

Knit Fabric Applications

Knit fabrics are preferred when movement and comfort are key:

T-shirts and polos

Activewear and athleisure

Underwear and sleepwear

Baby clothing

In the global apparel market, knit fabrics account for a large share of fast fashion and sportswear production.

Cost and Production Efficiency: Knit vs Woven Fabric

Manufacturing Complexity

Woven fabric production involves multiple steps: warping, weaving, dyeing, and finishing.

Knit fabric production is generally faster, especially for basic weft knits.

As a result, woven fabrics often have:

Higher setup costs

More stable quality in bulk production

Cost Comparison Table

| Factor | Woven Fabric | Knit Fabric |

|---|---|---|

| Machine investment | High | Medium |

| Production speed | Medium | Fast |

| Fabric waste | Low | Medium |

| Bulk consistency | Excellent | Good |

For long-term programs and private-label production, textile woven fabric is often more cost-effective over time.

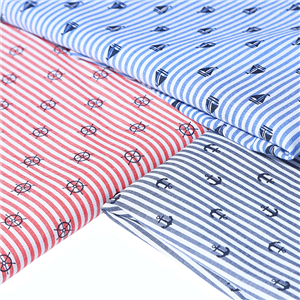

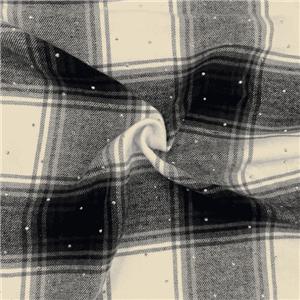

Appearance and Aesthetics

Visual Structure

Woven fabric offers:

Crisp lines

Clear textures

Defined patterns (checks, stripes, jacquard)

This makes it ideal for formal and semi-formal apparel.

Knit fabrics tend to look softer and more casual.

Print and Dye Performance

Woven cotton fabric performs exceptionally well in yarn-dyed and piece-dyed applications.

Knits are better suited for solid colors and simple prints.

For brands focusing on premium appearance, woven fabrics provide more design control.

Performance in Garment Manufacturing

Cutting and Sewing

Woven fabric is easier to cut and sew with precision, which is critical for:

Tailored garments

Structured silhouettes

Knits require specialized sewing techniques to prevent stretching and distortion.

Size Stability and Shrinkage

Woven fabric maintains shape better after washing.

Knits may shrink or lose shape if not properly finished.

For buyers prioritizing quality consistency, woven fabrics offer a clear advantage.

Sustainability Trends: Knit vs Woven Fabric

Eco-Friendly Fibers and Processes

Sustainability is reshaping textile sourcing decisions.

Both knit and textile woven fabric can be produced using:

Organic cotton

Recycled polyester

Low-impact dyes

However, woven fabrics often have:

Longer product lifespan

Lower replacement frequency

This contributes positively to sustainability goals.

Market Trends in 2025 and Beyond

According to recent industry data:

Demand for durable, long-lasting woven fabric clothing is increasing in Europe and North America.

Brands are shifting from fast replacement to quality-focused sourcing.

This trend favors high-quality woven fabrics, especially for B2B buyers.

Knit vs Woven Fabric: Which Should You Choose?

Choose Woven Fabric If You Need:

Structure and shape

Durability and strength

Professional or premium appearance

Long-term bulk supply stability

Choose Knit Fabric If You Need:

Comfort and stretch

Casual or sporty style

Fast production cycles

Lower initial cost

For many brands, the optimal strategy is a balanced portfolio using both fabric types.

Comparison Summary Table: Knit vs Woven Fabric

| Criteria | Woven Fabric | Knit Fabric |

|---|---|---|

| Structure | Stable | Flexible |

| Stretch | Limited | High |

| Durability | High | Medium |

| Appearance | Crisp | Soft |

| Best for | Shirts, trousers | T-shirts, sportswear |

This table is often featured in buyer guides and helps clarify decision-making quickly.

FAQs

What is the main difference between knit vs woven fabric?

The main difference lies in construction: woven fabric is made by interlacing yarns, while knit fabric is made by looping yarns.

Is woven fabric better than knit fabric?

It depends on the application. Woven fabric clothing is better for structure and durability, while knits are better for comfort and stretch.

Is woven cotton fabric breathable?

Yes, woven cotton fabric is highly breathable and suitable for shirts, dresses, and summer garments.

Does woven fabric stretch?

Traditional woven fabric has minimal stretch unless blended with elastic fibers or mechanically finished.

Which fabric lasts longer?

In general, textile woven fabric lasts longer due to its stable structure and resistance to deformation.

Final Thoughts: Making the Right Fabric Choice

Understanding the difference between knit and woven fabric empowers buyers to make smarter sourcing decisions. From structure and durability to cost and sustainability, each fabric type serves a distinct purpose.

As global demand shifts toward quality, consistency, and responsible production, woven fabric continues to play a critical role in apparel and home textile manufacturing.

At honryfabric, we specialize in supplying high-quality textile woven fabric, including premium woven cotton fabric and customized solutions for woven fabric clothing. With stable production capacity, strict quality control, and export experience serving global brands, we help buyers turn fabric choices into competitive advantages.

👉 Visit our homepage: https://www.honryfabric.com/

👉 Contact us for samples, pricing, or custom development: https://www.honryfabric.com/contact

We look forward to supporting your next fabric project with reliable woven fabric solutions.