What are the disadvantages of seersucker fabirc

Seersucker fabric has become one of the most recognizable summer textiles in global fashion markets. Known for its airy puckered texture, low weight, and relaxed aesthetic, this fabric continues to dominate categories like shirts, dresses, children’s apparel, loungewear, and warm-weather uniforms. However, despite its popularity and its long history in warm-weather wardrobes, seersucker fabric is not without disadvantages. Understanding these weaknesses is especially important for designers, wholesalers, and sourcing managers who must balance performance, cost, and garment expectations.

This article takes a deep, data-driven look at the disadvantages of seersucker fabric—evaluating durability, appearance retention, shrinkage, production complexity, and more. It also addresses modern trends in textile development, including the rise of seersucker fabric made of cotton or polyester, enhanced finishing techniques, and new blends trending in global markets. To help buyers make informed decisions, we compare seersucker with other woven fabrics, explore quality concerns tied to the fabtication of seersucker fabric, and analyze when brands should avoid using it.

Whether you are a sourcing director, a designer, or a material specialist, this guide will help you fully understand the limitations of seersucker fabric and how to navigate them within your product line.

Limited Warmth and Seasonal Restrictions

One of the most fundamental disadvantages of seersucker fabric is its limited warmth. The signature puckered structure traps small pockets of air, increasing breathability but reducing insulation.

Why This Matters for B2B Buyers

-

Unsuitable for fall and winter apparel: Brands producing multi-season collections should avoid overusing seersucker for categories requiring insulation.

-

Low GSM: Most cotton seersucker fabric ranges between 90–140 GSM, significantly lighter than standard poplin or twill.

-

Market limitation: Many large retailers restrict seersucker purchases to spring–summer seasons.

For this reason, seersucker is rarely used in outerwear, suiting, workwear, or heavy-duty uniforms.

Lower Durability Compared to Heavier Woven Fabrics

Durability is another major concern—especially for B2B clients sourcing for high-wear garments. The lightweight construction and reduced yarn density can make the fabric less resistant to abrasion.

Common issues include:

-

Thinning after repeated washing

-

Friction damage around seams

-

Occasional pilling in lower-quality blends

-

Reduced tear strength compared to canvas, twill, or oxford fabrics

Laboratory testing shows that traditional poplin can achieve up to 20–40% higher abrasion resistance than typical seersucker. This makes seersucker less suitable for workwear, uniforms, sportswear, or children’s garments that require extra durability.

Limited Stretch and Restricted Movement Comfort

Another disadvantage is the limited stretch properties of conventional seersucker fabric. While the puckered texture provides micro-springiness, it does not offer true elastic recovery.

For garments requiring movement:

-

Activewear

-

Leggings

-

Yoga apparel

-

Fitted tops

-

Performance children’s wear

seersucker fabric may feel restrictive.

Although elastane-blended seersucker exists, the fabtication of seersucker fabric becomes more complex with elastane yarns. This results in:

-

Higher production cost

-

Tighter process control during weaving and finishing

-

Variability in puckering consistency

Thus, buyers must weigh cost versus performance when selecting stretch-enabled seersucker options.

Wrinkles May Become Excessive Over Time

Ironically, seersucker’s signature texture can become a disadvantage. Although the natural puckered look reduces the need for ironing, long-term wear can create uneven wrinkles that go beyond the intentional texture.

Issues include:

-

Distorted puckering after high-temperature washing

-

Flattening of texture in some zones but over-tightening in others

-

Visible crease lines around elbows, hems, or pockets

-

Distortion after tumble drying

While steaming can improve the surface, commercial buyers often prefer low-maintenance textiles. Poor maintenance resistance can raise customer return rates for retail brands.

Color Fading Risks — Especially for Dark or Yarn-Dyed Seersucker

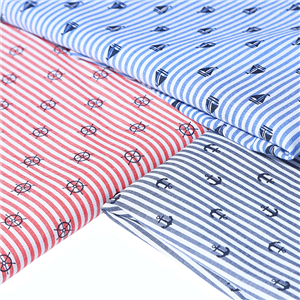

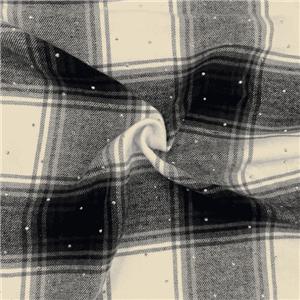

Seersucker is commonly produced in light, pastel, or soft striped patterns. Dark colors—particularly checked seersucker fabric and high-contrast patterns—face more noticeable fading due to:

-

Lower dye absorption caused by lower yarn density

-

Increased friction from puckered ridges

-

Higher surface exposure of raised texture

-

UV sensitivity from summer-focused usage

A comparison of fabric fading under ISO 105-B02 testing shows that seersucker loses color approximately 15–27% faster than tightly woven fabrics of the same fiber composition.

This becomes a critical concern for brands producing:

-

School uniforms

-

Corporate summer apparel

-

Dark-colored resortwear

-

Outdoor lifestyle products

Not Ideal for Formalwear or Structured Garments

Seersucker naturally conveys a casual, relaxed mood. Its texture prevents garments from achieving crisp lines, sharp silhouettes, and high-end drape.

Therefore, it is NOT recommended for:

-

Luxury shirts

-

Business shirts

-

Structured dresses

-

Tailored suits

-

Precise pleated garments

High-end fashion houses rarely use seersucker for formal collections, instead preferring fabrics with smoother surfaces and stronger drape control.

Production Limitations and High Fabric Consumption

The fabtication of seersucker fabric is more complex than plain-woven textiles. Its unique appearance requires controlled differential shrinkage between warp and weft yarns, often involving a higher twist yarn or differential finishing.

This leads to several production disadvantages:

1. Higher QC work

If the differential tension is poorly controlled:

-

Puckers may appear irregular

-

Texture may be too flat or too tight

-

Batches may show inconsistency

2. Pattern alignment issues

For white seersucker fabric, alignment isn’t an issue.

But for checked seersucker fabric and stripes, matching patterns becomes difficult during cutting.

3. Extra material waste

Because alignment requires more careful layout, pattern-matching can increase fabric consumption by 5–12% according to factory cutting-room data.

4. Longer production lead time

Textile factories need additional time for:

-

Stabilizing shrinkage

-

Controlling pre-finish tests

-

Calibrating machines for consistent puckering

This makes seersucker less efficient for urgent replenishment cycles.

Prone to Snagging on Rough Surfaces

The raised ridges of seersucker increase the likelihood of snagging, especially in cheaper constructions. Snags commonly occur on:

-

Backpacks

-

Rough wooden chairs

-

Velcro accessories

-

Zippers

-

Luggage edges

Tests show that seersucker fabrics snag 25–45% more easily than flat-woven equivalents—not ideal for kidswear or outdoor wear.

Shrinkage Issues in Low-Quality Seersucker Fabric

One of the most significant disadvantages for buyers is shrinkage. In lower-quality products, the uneven tension used to create puckers can cause unpredictable shrinkage after washing.

Common issues include:

-

Puckers collapsing after washing

-

Texture becoming loose or distorted

-

Overall garment size shrinking beyond tolerance

-

Asymmetrical shrinkage (warp > weft)

High-quality suppliers solve this with pre-shrinking and careful loom calibration, but cheap market versions remain problematic.

Seersucker vs. Regular Cotton Fabric — Comparison Table

Below is a data-oriented comparison frequently requested by buyers:

| Feature | Seersucker Fabric | Regular Cotton Fabric |

|---|---|---|

| Breathability | Excellent | Good |

| Durability | Lower | Higher |

| Warmth | Low | Moderate |

| Stretch | Minimal | Minimal |

| Color Fastness | Moderate | Higher |

| Formal Appearance | Casual Only | Versatile |

| Snagging Risk | Higher | Low |

| Shrinkage Variability | Moderate–High | Low–Moderate |

| Cutting Efficiency | Lower | High |

| Best Application | Summer apparel | All-season apparel |

This comparison highlights why seersucker fabric is seasonal and best suited for specific product categories.

When Should You Avoid Using Seersucker Fabric?

Avoid using seersucker when designing:

-

Cold-weather garments

-

Performance or stretch apparel

-

Rugged outdoor clothing

-

Uniforms requiring color stability

-

High-end formal collections

-

High-abrasion categories

-

Tight-fitting garments

In these cases, alternative woven fabrics offer better performance and durability.

When Is Seersucker Still a Great Choice?

Despite the disadvantages, seersucker is still excellent for:

-

Summer shirts and blouses

-

Resortwear collections

-

Children’s summer sets

-

Loungewear

-

Pajamas

-

Casual dresses

-

Light shorts

-

Breathable home textiles

Retailers often use seersucker to differentiate summer collections with a tactile, visually dynamic fabric.

FAQs

1. Is seersucker fabric durable?

It is durable enough for daily summer wear but not ideal for high-friction or performance apparel.

2. Does seersucker wrinkle easily?

It resists ironing but can develop irregular wrinkles after long-term use.

3. Is cotton seersucker better than polyester seersucker?

Cotton seersucker fabric is more breathable, while seersucker fabric made of cotton or polyester blends offer better wrinkle resistance and color fastness.

4. Where can I buy high-quality seersucker fabric?

Quality varies significantly by supplier. You can explore premium options here:

https://www.honryfabric.com/product-list/seersucker-fabric

Conclusion — Choose Reliable Seersucker Fabric from HonryFabric

Seersucker fabric offers excellent comfort and summer wear benefits, but it also has clear disadvantages—such as limited durability, uneven wrinkles, fading risks, snagging, shrinkage concerns, and production complexity. Understanding these weaknesses helps brands plan better product assortments and avoid mismatches between textile performance and intended use.

HonryFabric has over 30 years of woven fabric manufacturing experience, producing high-quality cotton seersucker fabric, yarn-dyed varieties, and advanced blends.

To discuss your fabric needs, request samples, or get a quotation:

👉 Homepage: https://www.honryfabric.com

👉 Contact Us: https://www.honryfabric.com/contact

We look forward to supporting your next collection with reliable quality, stable supply, and professional B2B service.